Technical Concept

Converter Platforms, Cables & co.

Offshore Converter Platforms

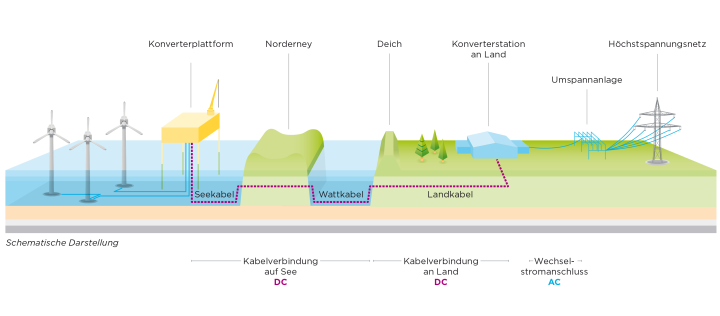

DolWin4 and BorWin4 will connect offshore wind farms (OWFs) in areas 3 and 6 with the mainland. Long sections of these connections will be installed as a submarine DC cables. Operating these connections as direct-current lines will enable us to transmit large amounts of energy over long distances with very low losses. The wind turbines, however, generate alternating current (AC). To convert this locally into direct current, we have to build a converter. A converter comprises various components, such as transistors, diodes, capacitors and inductors. And because it will be located in the North Sea, it has to be able to withstand wind and weather. That’s why we will install it on a platform with a wind- and weather-resistant housing. Cranes and a helipad will also be built on the platform to enable us to carry out maintenance and repair work.

We will connect the offshore wind farms to the respective converter platform by means of a “direct connection”. This involves running several 66-kilovolt submarine cables directly from the wind turbines to the platform.

The two converter platforms for DolWin4 and BorWin4 will be located far away from the coast. However, owing to their size we will construct them on land. Pile foundations will be used to ensure the platforms are securely installed on the seabed and will withstand the local conditions.

Submarine and underground Cables

The electricity will be transmitted from the offshore platforms to the coast by submarine cables. These will be buried in the seabed as environmentally compatibly and safely as possible. To perform this successfully, Amprion employs a number of proven laying methods. Particularly in ecologically sensitive areas such as the Wadden Sea, we take extra care to utilise eco-friendly laying methods.

To cross Norderney and the dyke on the North Sea coast, we use the HDD (horizontal directional drilling) method. With this method, we can realise longer crossings without removing the soil. Experts refer to this as a “closed” construction method. It means that we interfere only minimally with nature and the landscape and can even carry out the construction work in a comparatively short time. The only points at which we require areas for setting up construction site equipment is at the start and destination points of such a route. Closed methods do have disadvantages, including the higher costs that go hand in hand with such special solutions and the limited length of the line that can be laid.

On the mainland, we will lay underground cable from the dyke in Hilgenriedersiel (in the municipality of Hagermarsch) to the Hanekenfähr transformer station in Lingen. The task of building underground cable links in a cost-effective and “soil-friendly” way is a real challenge. But it is one that Amprion – working hand in hand with research institutes, experts and professional associations– is very willing to take up. Today we have the know-how to lay underground cables using a variety of construction methods. In addition to the closed construction method, an “open” method is also possible. With this process, the soil is excavated layer by layer and later backfilled in reverse order. Whether we decide in favour of an open or a closed construction method depends on a number of factors, such as the respective soil and ground water conditions and the natural geographical and also man-made features of the landscape– like rivers or motorways that may have to be crossed.